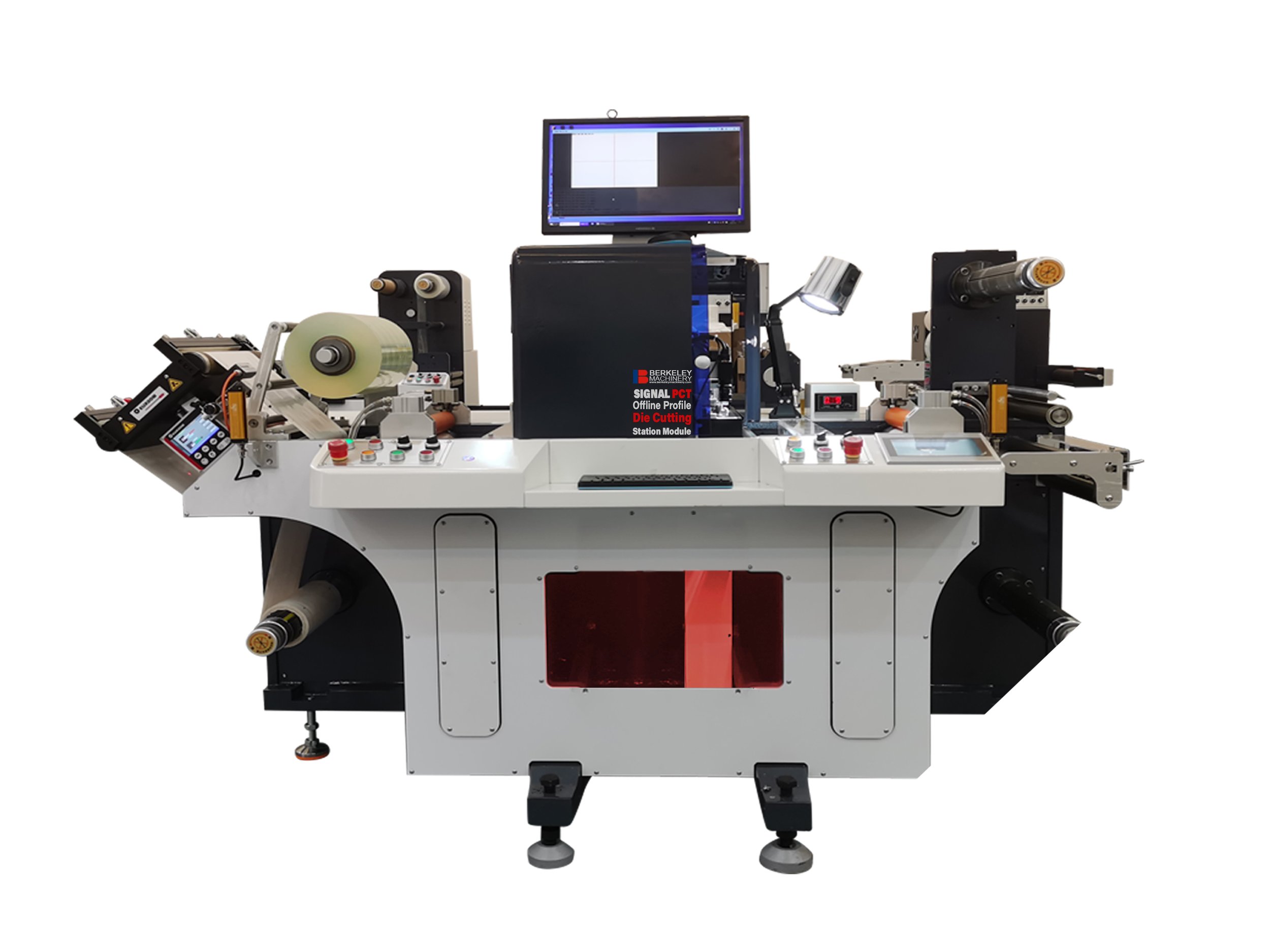

Offline Converting Machine

Maximum Material Width: 380mm (14.9”)

Maximum Converting Width: 370mm (14.57”)

Maximum die-cutting Width: 370mm (14.57”)

Description:

To generate further converting solutions on a pre-printed reel of material with the following specification. Includes customised options to manufacture a custom-made solution or patented product. Special features to add to pre-printed reels of labels, packaging, special material and products .

Full Electronic Servo Motor Driven Press

Mechanical Speed: 200m/min (656fpm)

Main Drive: 27kw

Lubricating System: Automatic

Control Panel: In the front of the Press

Air Pressure: 100PSI (0.6Mp)

Air Flow: 0.42m3/min.

Power Requirement: 380V ± 10% 50HZ

Substrate: 50-250gsm – paper 20-50micron – film

1 x Unwind Reel Stand for Quick loading of reels (up to 800mm dia) on 76mm Air Shafts to Unwind clockwise and anti-clockwise

Maximum Unwind Diameter: 800mm (31.5”)

1 x Infeed with servo registered drive to interface with other units through the converting process

1 x Electronic Web Guide for accurate guiding of material

1 x Full and Semi-Rotary servo drive flexo print station including Water chilled impression cylinder. The Flexo print station will run Full Rotary with matching print station and also Semi Rotary with unequal print cylinders, and will print, coat and spot varnish in register. Includes 1 x Print Cylinder 140T

Full Rotary Print Speed: 120m/min (393ft/min)

- Optional Upgrade to 150m/minSemi-Rotary Print Speed: 60m/min 196.5ft/min) - depending on the printing cylinder in ratio to the length of the printing plate, the speed will increase if the printing cylinder is closer to the length of the printing plate.

Print Registration: ±0.15mm

Flexo-Plate Thickness: 1.14mm (or specify)

Adhesive Tape Mounting Thickness: 0.38mm (or specify)

1 x Cold Foil Unit (Optional)

- Speed: 60 to 80m/min (Subject to the material and adhesives used)

Ink, Coating or Adhesive Drying:

UV Drive: (Mercury) MV 7.5kw each

SureMax MC (Optional) (Mercury Lamp) including Universal Drive to allow for future installation or replacement with LED UV Lamp (no need to replace the drive)

SureMax Infa-Red & Hot Air Combination Unit: (Optional) Variable Input Control for Infa-Red and Hot Air suitable for a wide range of print, coatings and special requirements. IR Temperature and Hot Air can be regulated accordingly OR can be run individually.

LED Drive: (Optional) 3.2kw

1 x Flat Die-Cutting and Embossing Module** - world’s fastest system

* Perfect Pressure 54-ton capacity hot foil and embossing module - with multiple foil feeding across and along the web.

Flat Die-Cutting and Embossing Speed: 400 imp/min(120m/min) (393ft/min)

- Optional Upgrade to increase to 150m/min (494ft/min)Flat Die-Cutting and Embossing Size: 350 x 350mm

Flat Die-Cutting and Embossing Plate Thickness: Universal gauges (allows for variable adjustment to Flat Die-Cutting and Embossing Plates) - to allow you to source locally.

Optional Foil Feature

1 x Hot Foil (Optional - Die-Cutting Station required**)

Hot Foil Stamping Speed: 100 imp/min*

Hot Stamping Register: ± 0.15mm

Maximum Size of heated platen: 350 x 350mm

1 x Full & Semi Rotary Die Cutting Unit

Full Rotary Die-Cutting Speed (Average): 160m/min (525ft/min)

Semi-Rotary Die-Cutting Speed (Average): 75.5m/min (247ft/min) - depending on the die-cutting cylinder in ratio to the length of the die plate, the speed will increase if the die-cutting cylinder is closer to the length of the die plate.

1 x High Speed Snowball Waste Rewind unit – to rewind reels with a driven pressure roller, to provide compact rewound reels and allow for difficult self-adhesive labels to be produced/extracts difficult waste profiles to be rewound.

1 x Outfeed Unit

1 x Independent Product Rewind shaft - 800mm (31.5”)

or Dual Rewind Shafts (Optional):

Top Rewind Diameter: 600mm (23.6”) or

Bottom Rewind Diameter: 800mm (31.5”)

TOOLING INCLUDED

1 x Print cylinder (140T)

1 x Ceramic engraved anilox roller

1 x Magnetic die-cutting cylinder (140T)

1 x Set of consumables and spare parts

OPTIONS:

Full rotary flexo with UV

Mercury UV Unit

LED UV Unit

Full rotary die cutting

Full & semi rotary die cutting

Flat bed die cutting - High Speed 120m/min, 400 imp/min

Hot stamping*

A flat die cutting unit is needed for this option*

Flat-Bed Silk Screen Printing Unit with servo drive, including Flat-Bed Screen unit with intermittent linear printing of silk screen images. Quick tool-less change of the silk screen frame, including UV …

Crossover Module - Peel and Read -to create multi-layered informative or promotional products - 2 ply (3 pages) and 3 ply (5 pages)

Dual Rewind

Cold Foil

Lamination - to have a pre-printed web to be laminated in register to the main web

Sheeting & Conveyor (with Automatic batching of sheets through the automated speed control of the conveyor, which are then delivered to a vertical stacking plate)

Batcher Stacker - Automatically counts the labels and batches them into stacks.

Slitting Station with 4 Rotary knives - With lateral movement of the slitting knives

Automatic Slitting Station - Automatically changes the width of the slitting requirement.

Manual Turret rewinder

Fully-Automatic Turret rewinder with automatic unloading of the finished reel. Can be connected with an automatic continuous packing line with robotic controls.

Corona Treater

Web cleaner (single side)

Anti static (2 bar and one controller)

Rail Mounting System - allows for special integration for producing special products.