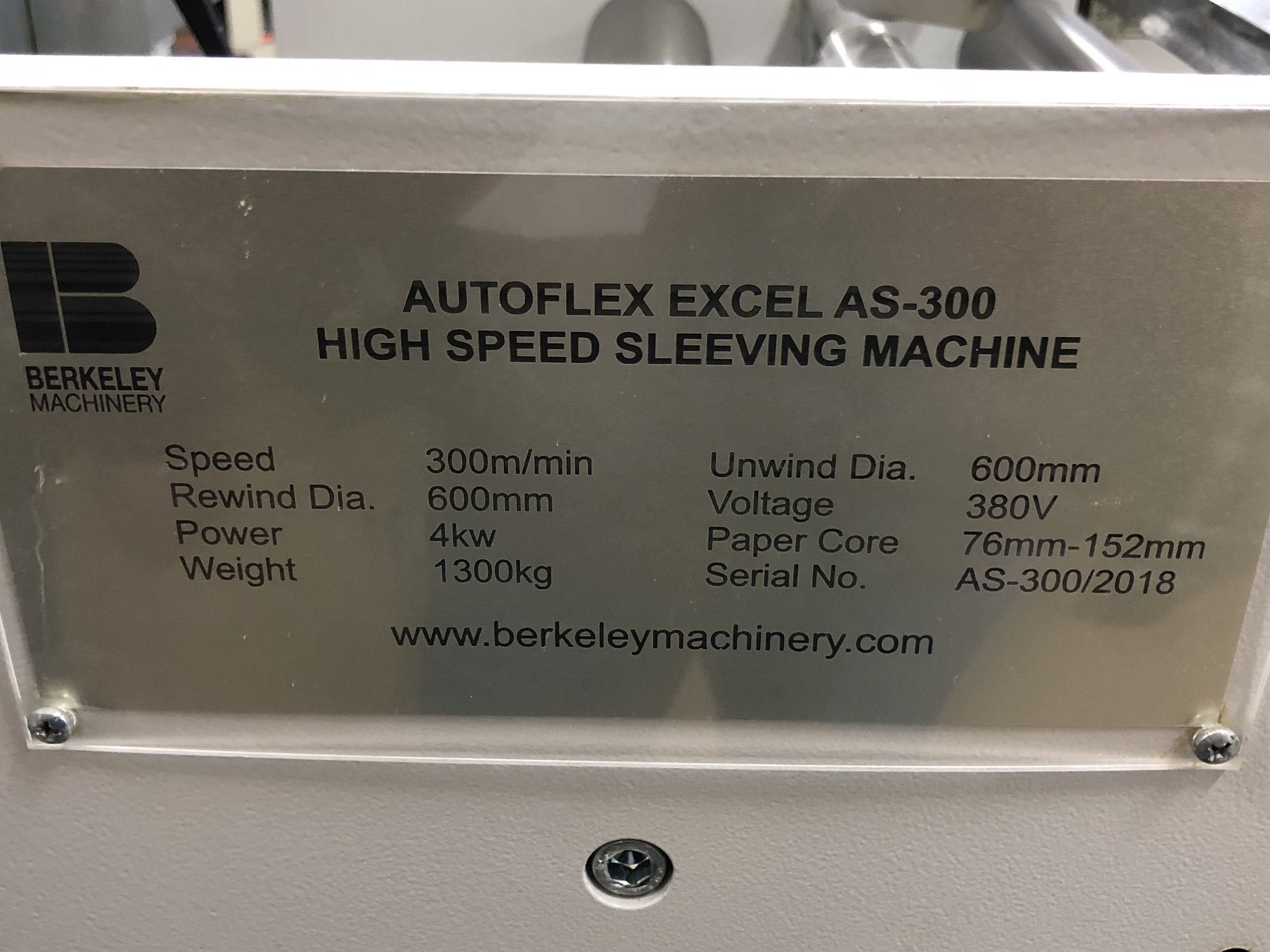

Autoflex Excel AS-300 Sleeving Machine

REF: BM00594

Automatic High Speed Plastic Sleeve Making Machine

Including AS U 300 Unwind with Automatic Reel Lift Upgraded model with upgraded features

Year: 2018

Web width: 600mm

Max flat tube width: 280mm

Min flat tube width: 15mm

Production speed of sealing: 350m/min

Precision: +(-) 1mm

1 x Unwind unit with 76mm (3”) or 152mm (6”) pneumatic airshaft and twin side frames to take maximum unwind diameter of 600mm (23.62”) with infinite control by particle magnetic brake (2.5kg brake) with automatic reel lift, as shown in above photo including AS U 300 unwind with automatic reel lift

1 x Automatic tension control system for perfect web control through PLC, and tension system provided by Techmach model AWG 5000 EPC. This system has been perfected for control of shrink film substrates, including other film materials suitable for sleeving

1 x Infeed system to increase mechanical tension on sub standard material or difficult material with various tolerances across the web width

1 x Web guide system with U-type sensor, using floating shaft (the shaft moves sideways from the signal from the sensor method to allow for the material to be guided accurately through the machine)

Process unit as follows:

a) running pneumatic perf station to allow for tear out or for special sleeve products

b) variable guide plate (turns the material into a sleeve)

c) electro pneumatic glue nozzle dispensing head to glue sleeves, including control unit, which automatically controls the outflow of glue with the speed of the material being converted on a step-less control system (continuous adjustment of web speed), which allows the gluing and sealing heads to be integrated with an automatic peristaltic glue pump system connected and integrated with the machine’s PLC

d) process head with rubber and steel impression cylinder, forming material to a flat output surface for perfect production of rewound reels, which are required for high speed sleeving on integrated packaging lines

e) ceramic, dynamically balanced path rollers for high speed converting

f) variable out feed unit

g) two cantilever out feed rollers to assist winding of product

Drive & Control Systems:

Automatic unwind and rewinding is controlled by a PLC built from the following components and following drives:

One high frequency stroboscope

One Mitsubishi Model FX2N-32MR PLC from Japan

One Mitsubishi Model FX2N-4D / A1 from Japan

One Mitsubishi Model FX2N-2A / D1 from Japan

One Yaskawa Model H-1000 1.5kw speed control system One Yaskawa 1.5kw independent drive motor

One 7” touch screen operating monitor from Wienview

Anti static brush devices included for perfect running of film

1 x Unwind unit to unwind reels up to 600mm diameter on 76mm cantilever shaft with a magnetic clutch sensing brake.

1 x Rewind unit to rewind reels up to 700mm diameter, with independent rewinding drive including oscillating 76mm (3”) or 152mm (6”) shaft for perfect rewinding to avoid coning of the reel at high speeds, using control with a vector frequency drive and motor manufactured by ABB (1.5kw). Auto air valve is included, to expand or decrease the airshaft.

1 x Operator panel with full operation controls

Total Power: 5kw

Power requirements: AC 380V, 3 phase, 50Hz or specify power of country.

Air supply: 100PSI (0.6Mp)