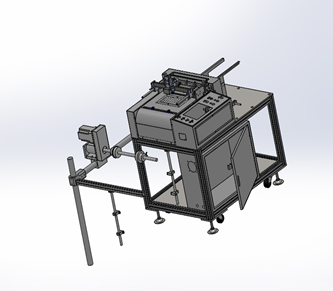

Apollo BX 350-STPR1

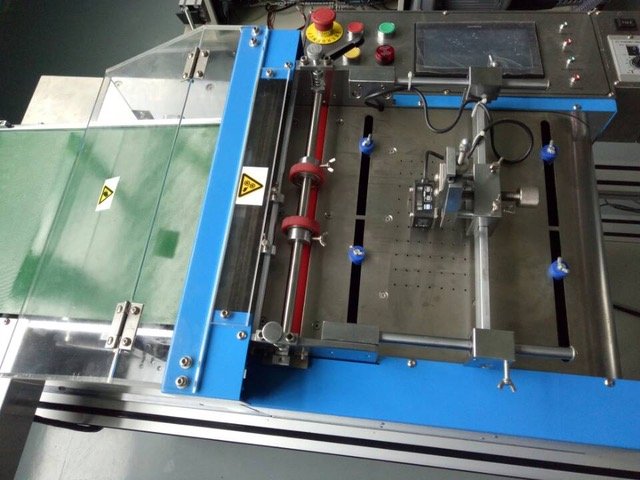

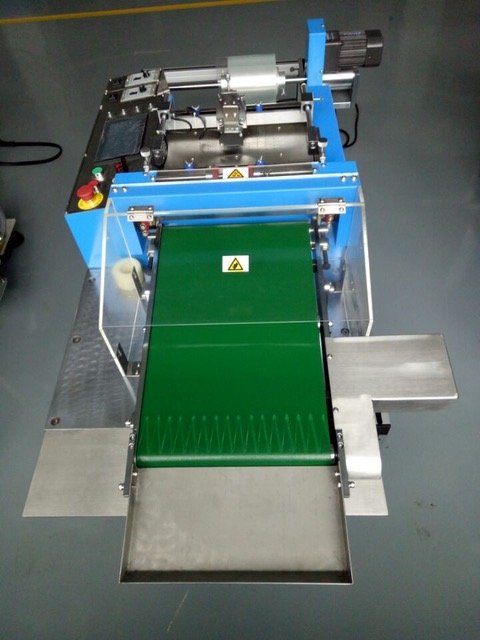

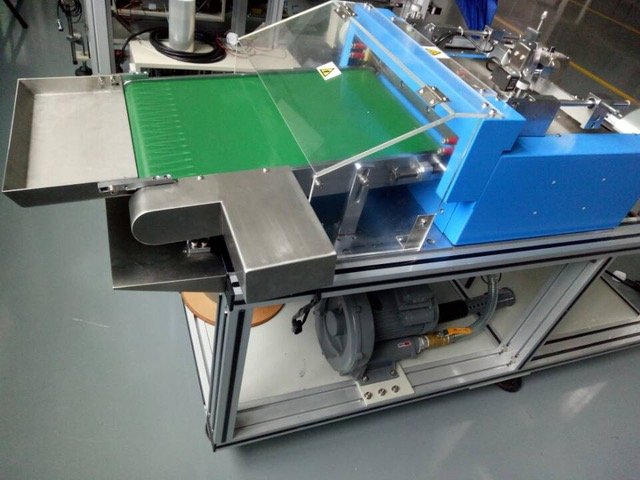

Step and Repeat Cutting Module

The Apollo BX is a step and repeat cutting and sheeting machine which can cut a variety of products like labels, film, and special industrial laminates and products used in the automobile industry. This module can also be linked to a continuous finishing line to cut other specialised products which have been laminated prior to the process of the sheeting.

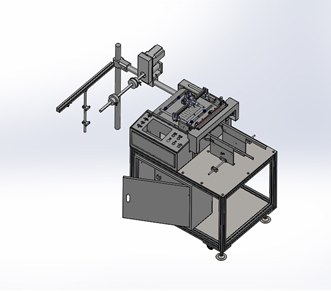

For the purposes of a stand alone sheeting unit we can integrate a cantilever reel unwind stand with automatic tension, and sensor to read the optical mark on the reel of label or industrial material. The sensor provides a signal to the electronic drive on the sheeter to allow the knife to cut the sheets in precise lengths.

Integration of the reel unwind with the sheeting module.

Construction:

Web Width: 350mm (13.7”)

Cutting Width: 350mm (13.7”)

Cutting Length Precision: + / - 0.12mm

Mechanism: Step and Repeat drive with sensor

Cutting System: Cold knife

Cutting Speed: 10,000 - 12000 pieces per hour subject to cut length required

Minimum Cut length: 10mm (smaller cutting lengths can be cut subject to material

Maximum Cut length to stacker: 350mm (13.7”)

Maximum Cutting Thickness: 0.01-8mm depending on material

1 x Cantilever Unwind Shaft with motorised unwind with locking collars for different size cores to take a maximum reel diameter of 330mm (maximum weight 15kg)

1 x Auto Tension system

1 x Sensor with loop control

1 x Step and Repeat Sheeting Module

1 x Platform table with integrated drive

1 x Operator Control Panel with keypad input and LCD display for cutting length etc

1 x Variable Stacking table with guide side plates

Power: 220V 50/60Hz

Optional Extras:

Reel unwind stand to take 500mm dia.

Reel unwind stand to take 600mm dia.

Razor/Slitter unit with cross knife and side trim

Antistatic Bars

Any other requirements can be supplied subject to discussion