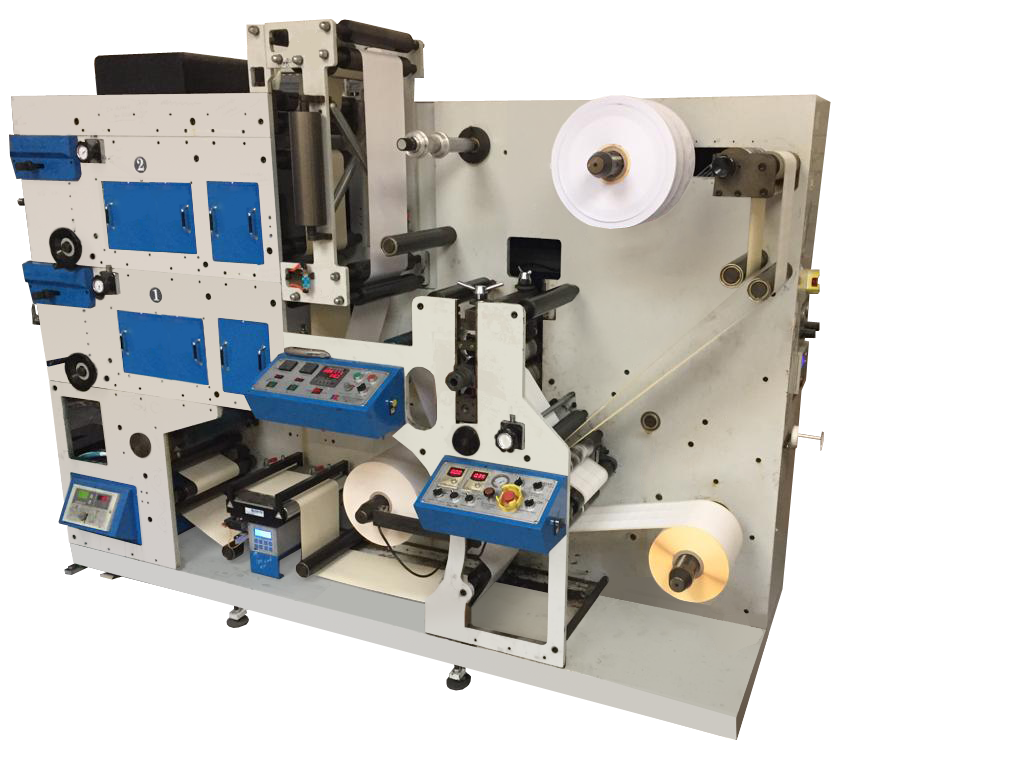

Apollo 330ZS - 2 Colour

REF: BM00557

Web Width: 330mm Printing width: 320mm

1x Unwind unit to take reels of 600mm dia. on pneumatic shaft with auto tension control.

1x Infeed unit to control length and accurate feeding of variable materials, allowing for a range of materials from 20 microns to 350 microns. Thicker materials can be run subject to testing for a variety of industrial products.

1x Register/auto tension control. This is an independent electronic control system which gives infinite control of the tension and allows for the print units to produce excellent print quality

1x Electronic web guide with electronic sensing to adjust the material accurately through the print units, press and converting process stations

2x Variable flexographic print towers to print from 8" to 20" circumference with manual 360° registration. Each unit can be individually disengaged if required. The print unit has a unique design to allow for variation of different print materials to run through the print units without exerting pressure on the drive gears. Therefore, alleviating any possible mechanical pressure through the print units to avoid bar or gear marks. The user friendly adjustable platform and tool-less assembly system for quick change of anilox and print cylinders make the press highly productive when changing from one job to another. The press comes with a motorised control for the continuous running of the anilox and metering roller when water based inks are used. This is to stop the drying of water based inks on the anilox and plate cylinder when the print cylinder is disengaged The print cylinders are a sleeve type system mounted on a removable shaft which reduces manufacturing of print cylinders and faster change-over.

2x IR Hot Air Dryers for drying of water based inks.

1x Turn bar unit. Designed with pneumatic bars to enable the printing on the reverse of the material allowing for the printing of complex and unique design jobs

1x Matrix Label Waste Skeleton** rewind shaft to take reels up to 500mm dia. on a cantilever pneumatic shaft with independent tension control allowing for the matrix waste skeleton to be rewound easily and the adjustment of tension to allow for working with difficult materials

1x Die cutting station to take magnetic or engraved die cutting cylinder up to 20" repeat. The die cutting station has a special design allowing for the substrate to be die cut on the face or reverse of the material. The design of the die station allows us to supply die adaptors which will allow for other manufacturer’s dies to work in the Apollo press (subject to receiving the design of the die to work in our die station)

1x Slitting station which allows for film, paper, board and industrial laminates to be slit with a rotary type slitting system with top and bottom cutters.

1x Product rewind shafts to rewind reels up to 600mm dia. on 76mm dia. pneumatic shaft.(Option for a 2nd Product Rewind)

1x Special Plate Mounter with optical magnifier. This is a table top plate mounter, which has a viewing magnifier and a mounting system to produce perfect mounted plates for accurate and excellent print results when mounted on the print units

6x print cylinders, with helical gears, included in price

1x set of ceramic anilox rollers, with helical gears, included in price – up to 600dpi

Optional Extras:

Anilox Cylinders from 250dpi to 650dpi

Anilox Cylinders from 650dpi plus

Print Cylinders from 8” to 22” circumference

Delamination/Relamination (Printing on the Adhesive Side)

Die Cutting Cylinders from 8” – 20” circumference

Ultra sonic anilox cleaner – Model

UV Units

Chiller Rollers

Refrigeration Unit for Chiller Rollers

Corona Unit

Cold Foil (can only be done on last station on Apollo)

Video Inspection Unit

*Refrigeration Unit

Sheeting Conveyor Table to deliver cut sheets with independent drive and controls

*Upgrade for 1200mm (47.24”) unwind & rewind

**Matrix Waste Skeleton Label Rewind Unit Snowball Design Upgrade

…and any other custom-made solutions to allow the customer to produce a patent or idea.