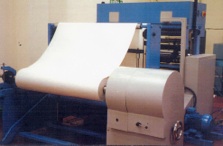

The Autocut SR1350

Specification

Web Width: 1350mm

Unwind diameter: 1250mm x 70/76mm core on pneumatic expanding shafts on reel stands made from 45mm cast iron. A cast iron cross brace frame of 100mm to support both side frames

Operating Speed: Up to 500m per minute through digital drive and P.L.C control panel. For small roll production the speed is normally reduced by the operator

Maximum Rewind diameter: 150mm for automatic ejection. 300mm for manual ejection

Minimum Rewind diameter: 30mm for automatic ejection

Minimum Core diameter: 12mm O.D.

Substrate: 45gsm to 100gsm (weights of 120gsm have been tested with excellent results)

Drive: 10hp motor

Brake: Magnetic particle brake with infinite control to digital drive and main control panel

Slitting System: Scissor type with 24 sets of rotary cutters with holders top and bottom. Minimum slitter width 17mm

Tension: Automatic web tension system by dancer roll control and assisted by guide rollers

Rewind: Surface type rewind system and one spreader roll before rewinding

Gluing Unit: Suitable for gumming and sealing of finished roll. System can also be used for 2ply rolls

Other Features

Automatic finished reel pusher which is designed to push rolls up to 150mm dia.

Pneumatic linear cutting system

Rider rollers will be pneumatically controlled in lieu of spring control

Automatic pressing of paper with tuck in system

Complete bottom cutter shaft assembly for one size

Two number of rewind shafts for I.D. 12.7mm and one other size will be supplied with the machine

Optional Extras

24" vibrator bowl and core loader

Conveyor to take finished rolls to packing line, including roll separator for interlocked cores